Laser Photonics Introduces CleanTech™ Handheld NCX with IIoT! — Laser Photonics

Handheld laser cleaning equipment features improved network connectivity and safety features.

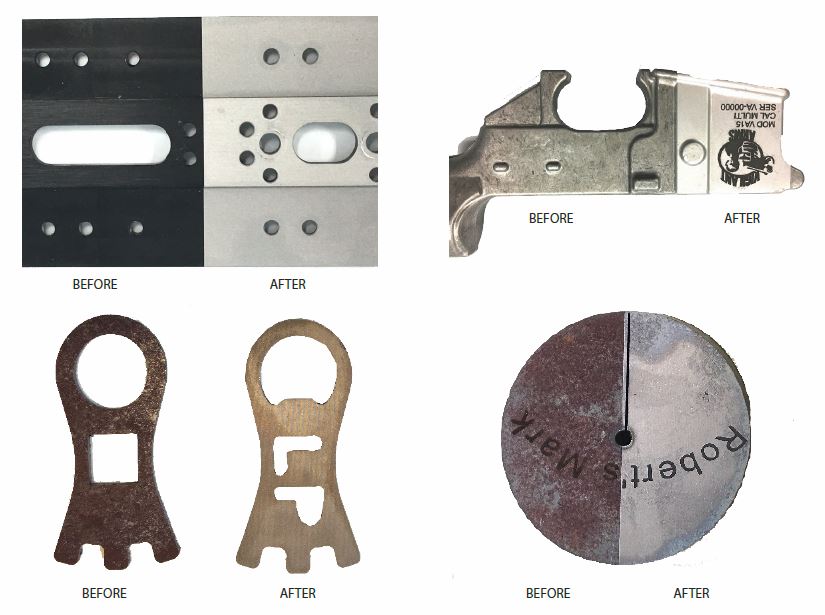

CleanTech Samples

ORLANDO, Fla. – Dec. 15, 2017 – PRLog — The CleanTech™ Handheld NCX laser surface cleaning machine is complete, industrial-grade, high precision portable laser cleaning and surface conditioning system – The first handheld laser featuring IIoT (Industrial Internet of Things) connectivity, increased portability, enhanced safety/operating features and made in America. Not everything fits neatly in a box, so the CleanTech Handheld NCX is ruggedly built for remote surface cleaning and preparation.

Laser cleaning is a non-contact, environmentally friendly process for removal of surface coating from metals, concrete and delicate substrates such as composites – with minimal impact on the base material. Laser cleaning is applicable in nearly every industry and can be applied to glass, ceramics, metals, concrete, plastics and much more. Laser Photonics’ portable system expands the cleaning from the floor to the field. Laser cleaning and removal can be applied to surfaces of bridges, aircraft, large vehicles, trains, etc – in addition to small parts and sensitive materials.

The CleanTech™ Laser System has a distinct advantage over costly traditional methods, such as chemicals or abrasive blasting systems. These traditional methods typically have a negative environmental impact, hazardous fumes and can wear on the substrate and damage the material. CleanTech™ Laser Systems remove coatings, contaminants and residues with the non-contact, non-abrasive use of high energy laser sources. CleanTech is the most cost effective, efficient and safe method of industrial cleaning, rust removal, paint removal and surface preparation. Utilizing our proprietary technology, CleanTech cleans materials faster and better than other system on the market.

CleanTech™ Handheld NCX surface preparation laser Features:

• State of the Art, Air-cooled, Ytterbium Q-Switched Fiber Laser

• 1 mJ Pulse Laser Standard (0.5mJ, 1.0mJ, 2mJ or Custom 150mJ Max)

• Class 1 Laser-Rated Safety Viewing Port

• Wide Range of Cleaning Parameters, Standard and Custom Optics Shapes

• Assist Inert Gas System

• Red-Diode Pointer

• Galvo-Scan Head with 160mm F-Theta Lens (4″ x 4″ Marking Area)

• 4″ x 4″ Processing Chamber

• Network Capability-Enhanced Control Card/On Board Removable Memory

• Portable Cart Industrial-Grade Laptop PC Includes CleanTech Software

• Cleaning Head with Dual Activation Switch and Mechanical Interlock for Safety Compliance.

• Laser “ON” Locked Contact Switch for Operator Safety

• Integrated Mini-Exhaust System

• Dust Collector

• Maintenance-

• Continuous Operation Under High-Shock, Vibration, and Dust Conditions

• Easy & Safe to Operate

• 12V/24V DC Power Source – 110V/220V AC Power Source

• Flexible 3 Meter Optical Fiber Cable

• PipeWrap Attachment Optional

• 3D Scanning Optional

Applications:

• Metal Parts Cleaning

• Depainting

• Anodizing Removal

• 3D Surface Cleaning and Conditioning

• Surface Texturing

• Cosmetic Surface Conditioning (replaces bid blasting)

• Selective Paint Removal

• Mold Cleaning

• Joining Pre-Treatment Cleaning

• “On-The-Fly”

• Ablation (Anodized, Painted or Coated)

• Paint Stripping and Removal

• Rust and Corrosion Removal

• Degreasing

Materials & Product Suitability:

• Aluminum (Anodized/Polished/

• Stainless Steel/ Mild Steel

• Titanium

• Copper

• Brass

• Nickel

• Galvanized Metals

• Multi-Coated Materials

• Painted Metal Alloys

• Plastics

• Polypropylene/

• Cast Iron and Chrome

• Chrome

• Carbide

• Rubber and PVC

• Composites

• wfv and More

http://www.laserphotonics.us/

CleanTech is also available with Flexion Technology in the large format CleanTech Titan, NEW industrial grade Titan Express, OEM, robotic systems, and turnkey LaserTower CT series featuring CleanTech MegaCenter. Flexion technology provides a distinct advantage over other laser cleaning systems on the market. Flexion technology allows CleanTech to remove rust, paint, anodization, and other surface materials in areas that are typically difficult to reach. Most other systems are statically positioned which limits the laser cleaning ability to only the static path of the trajectory beam. CleanTech systems can be outfitted with a 3D scanner for job slicing and 3D path generating trajectory.

Laser Photonics maintains an applications lab for processing customer samples and assisting with process development. Our applications lab has the latest testing equipment to analyze all of your application needs.

For cleaning applications, we provide the highest quality analysis of each and every mark using our Surface Quality Assessment™ (SQA™) soft¬ware. With our SQA™ software, we have the ability to guarantee and verify the accuracy and quality of our surface treatment.

The Laser Photonics brand is the industry leader in developing high-tech Fiber, UltraFast, UV, CO2 and Green laser systems. Laser Photonics specializes in advanced, innovative, latest generation laser systems, processes and technologies. We have delivered fiber laser cutting and engraving machines to many industries worldwide such as defense, government, aerospace, automotive, biotech, medical, manufacturing, food processing and many more. Contact us to learn more about our laser 3D metal printing (additive manufacturing)

Watch CleanTech in action: https://youtu.be/